_TECproducts – High Performance Valves

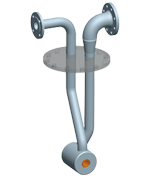

_TECpress

_TECsteam

_TECtemp

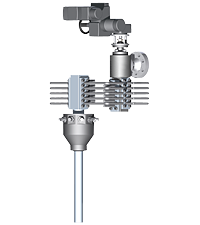

TECtemp HT L

_TECtemp HT R

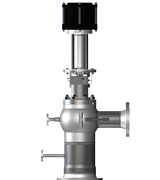

_TECtemp HT V

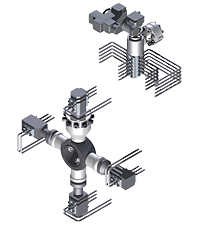

_variTEC

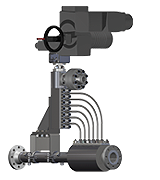

_TEC artec

Power plant application areas

Power plant application areas

Conventional power plants are used for electricity generation. For example, these include lignite, hard coal or gas power plants. Very different types of primary energy are converted to electric current in a power plant.

Basic functionality: Water is heated by combustion in the steam generator in the core of the power plant. Turbines are driven at very high pressure and temperature with the steam produced from this. These are coupled to electricity generators. Afterwards, the steam is condensed to water and returns to the steam generator.

Valves from TEC artec have been used successfully for many years in many national and also international industrial and large power plants.

Information about power plant application areas

_TEC artec

Gas application areas

Gas application areas

Valves in gas networks are important shut-off or control valves with high requirements for operational safety and reliability. For example, our valves are used in compressor stations.